Semiconductor Industry supply-chain value-stream analysis

How the most abundant material on Earth derives additional value through the industry supply chain to end up in everything around us?

Semiconductor materials are ubiquitous - our pockets, in what we wear and used richly in everything around us to generate, process and consume massive streams of data than ever before in history.

One of the basic raw materials in these electronic devices humming with constant streams of data is chips made of pure silicon (with some intentional doping of impurities). Here is a fact: The mass of Earth's crust is 59 percent silica aka silicon and oxygen, SiO2, the main constituent of more than 95 percent of the known rocks.

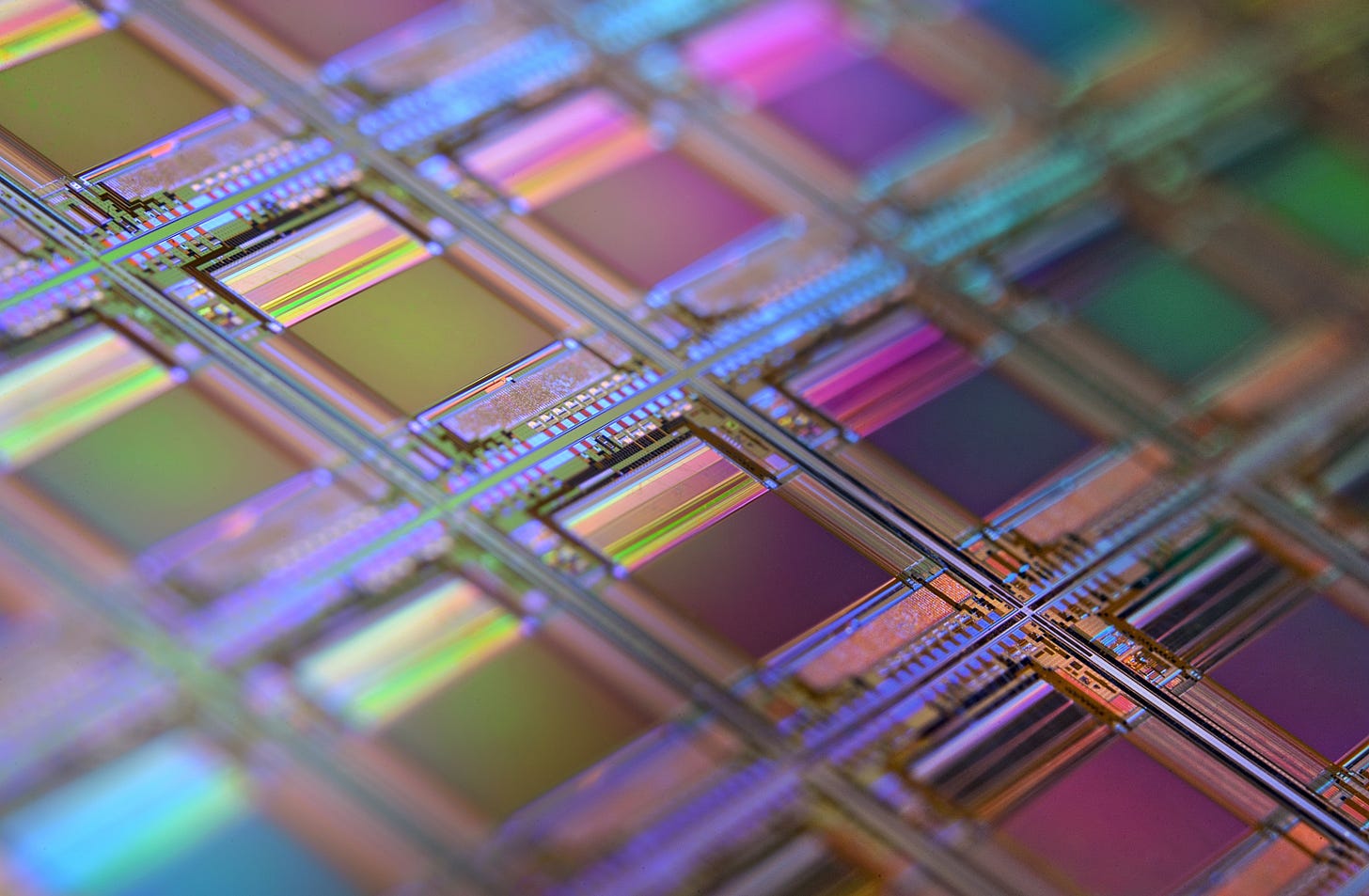

The chip manufacturing is a highly advanced, complex process that takes the dedicated contract fab companies like TSMC and Global Foundries a few months to complete. At the same time, they are pouring R&D capital into making technology nodes into ever shrinking smaller geometries (nanometer-scale transistors) to increase capacity for the insatiable demands without having to build a new fab (a very costly endeavor). Same 12-inch diameter wafer area with higher transistor density due to smaller geometry yields more devices and better utilization of the fab’s existing and expensive equipment.

Let’s look at gross margins (GM) in the entire supply chain from the fabs to the semiconductor design companies to the leading consumer device companies to the electronic retailers to see where the value is created and added as a value stream analysis. I will preface this by saying it is a simplified view to get an understanding of the semiconductor industry supply chain and value accumulation.

Note that, I have listed a typical gross margin as a general illustration and these are subject to change from company to company. Going with these assumptions, if there is a $15 input cost of the the raw material silica and other direct costs to manufacture a wafer of functional semiconductor devices, it ends up accumulating value in the chain as shown above and ends up as $100 worth of electronic device content in the form of chips that can store and process data from inputs to outputs as demanded by the software components involved in the use-case.

Another way to look at it is for every $100 value of retail semiconductor (electronic device chip) content sold in the world, approximately $30 flows as revenue to the semiconductor fab, $25 flows as gross profit to the chip design company, $25 flows as gross profit to the consumer device design/manufacturer/distributor company and the remaining $20 flows as gross profit to the device retailer.

Now, the consumer device company from the third step above can be further broken down into its own value stream with a supply chain of ECM (Electronic Contract Manufacturer), Design Operations and Distributor partners to see how its revenue is distributed in its own supply-chain value creation. For example, Apple is a consumer device company that designs the product in-house, and does marketing and retailing for most of its sales and utilizes Foxconn as their ECM.

For most semiconductor design companies that have significant R&D in developing new designs for complex customer requirements, it usually makes sense to use a dedicated, high-tech fab company for contract manufacturing in order to:

Avoid the high capital structure in semiconductor manufacturing

Avoid the R&D costs associated with incredibly fast shrinking process nodes

Avoid any idle fab capacity due to new designs in the pipeline and not ready to be manufactured or sporadic demand cycles.

It is a very careful balance in this supply chain for the fabs to maintain expectations of on-time deliveries (OTDs) v/s excessive inventory days. The demand swings into high gear a few months before the launch of major consumer electronic devices around the holiday season. So, it becomes very important to ramp appropriately and quickly without costly delays; and delays might also lead to future order cancellations due to missed delivery dates.

In conclusion, such value chain analysis can be done for any industry and may help to answer questions like if it is beneficial for a company in the middle of the chain to be vertically integrated or not for a better business model. This analysis should consider whether the improvement in its profitability will justify the return on investment required for absorbing more of the value chain. I hope this helps the investor to determine the value-add aspect for investment analysis.